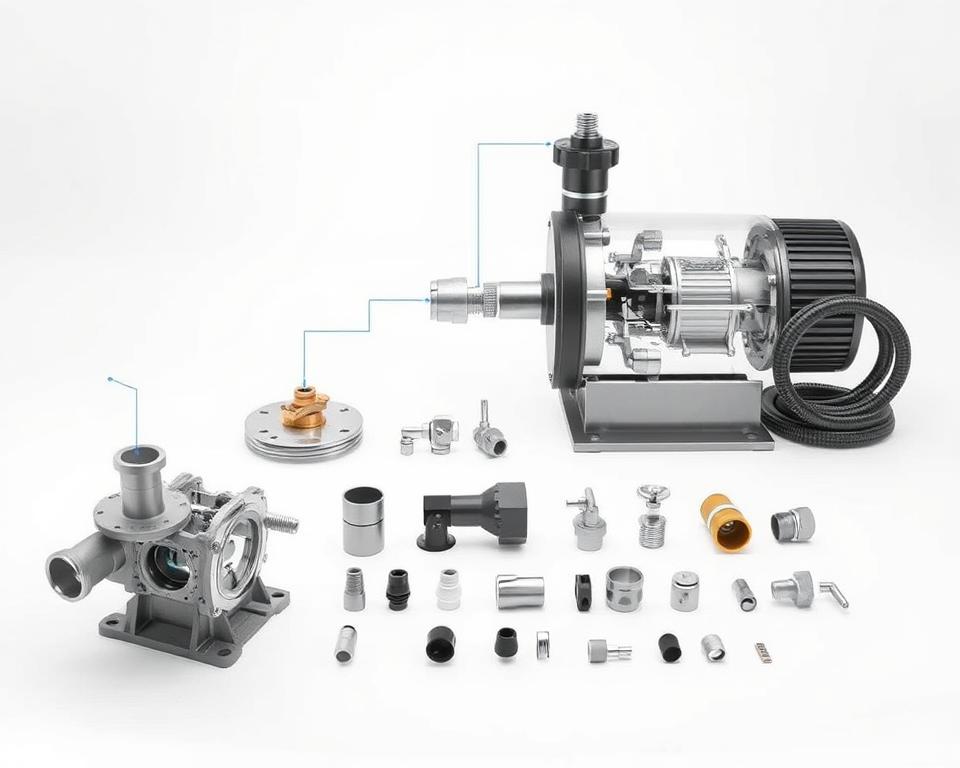

Shurflo Liquid Pump Schematic – Parts Supply for Installations

Incorrect installation of water pumps can substantially diminish their performance by up to 30%. It’s vital to comprehend the operation of the Shurflo Water Pump diagram for optimal operation and robustness. Each component within the diagram serves an essential purpose in the pump’s function. We will explore the significance of understanding these Shurflo fittings, employing the schematic to demonstrate their setup and how they operate in unison.

Parts Supply for Installations is your primary source for every Shurflo Water Pump part required for setup and maintenance. Learning via the Shurflo Pump parts diagram empowers users to proficiently manage installation and servicing. This foundation aids in making informed choices for the optimal and reliable performance of their water pumps.

Understanding Shurflo Pump Systems

Shurflo Water Pumps are at the crossroads of ingenuity and functionality, fulfilling the requirements of various uses. This section seeks to provide an in-depth overview of Shurflo Water Pump models, their particular applications, and the merits of selecting these pumps. They are famed for their advanced technology and performance.

Overview of Shurflo Pump Types

Shurflo’s assortment comprises Pump models like the diaphragm and horticultural series, crafted for varied demands. The membrane models are celebrated for their sturdy design and efficiency in moving liquids. Examples such as the 2088-343-135 and 2088-343-500 deliver robust performance with remarkable flow and pressure specifications.

The farm series, alternatively, is built for optimal fluid conveyance in farming environments.

Implementations of Shurflo Pumps

The flexibility of Shurflo Pump systems permits their use in a diversity of environments. They are typically utilized for:

- Agriculture: Provides solutions for crop irrigation and fertilization.

- Recreational Vehicles: Guarantees uninterrupted Water Pump service with controlled pressure.

- Residential: Well-suited for yard upkeep and home Water Pump installations.

This versatility allows these Pump systems to integrate smoothly into different systems, proving their versatility.

Benefits of Choosing Shurflo Pumps

Choosing Shurflo Pumps brings several perks. Their self-priming capability eliminates the need of manual operation startup. They also have resilience to chemicals, enhancing their durability in adverse settings. Convenient access to Shurflo diaphragm Pump parts simplifies upkeep, enhancing the pump’s lifespan while reducing idle periods. Additional advantages of Shurflo Pumps include:

- Stable performance that can be customized with adjustable pressures.

- Easy installation supported by the Shurflo pumps parts catalog.

- Diverse pump fittings for seamless integration with existing setups.

With these attributes, Shurflo Pump systems promise optimal functionality and trustworthiness. They ensure operation continuity, providing users with confidence in their functionality.

The Shurflo Water Pump Schematic and Its Significance

The Shurflo Water Pump schematic is vital for comprehending its components and functions. By reviewing the Shurflo Water Pump schematic, users can construct, debug, and uphold effectiveness. This schematic is indispensable for locating the necessary Shurflo Water Pump parts. Proper arrangement ensured through the schematic ensures peak performance.

Essential Elements in the Schematic

The Shurflo Water Pump schematic illustrates vital elements required for effective function:

- Engine: The motor, the central unit of the Pump, propels the rotor, delivering flow rates between 41 and 168 GPM.

- Diaphragm: Supports consistent flow and pressure.

- One-Way Valves: Crucial for preventing backflow, these devices secure that water moves correctly.

- Housing: With a maximum pressure of 200 PSI, the housing ensures durability.

Understanding the Shurflo Water Pump Diagram

To interpret the Shurflo Pump schematic, one must note particular icons and labels:

- Study the layout of parts shown in the schematic.

- Identify the flow direction as shown by arrows among parts.

- Check notes for details like wire sizes and mounting options.

Understanding this schematic is crucial for efficient construction, servicing, and determining required elements.

Fitting Shurflo Water Pumps

Setting up a Shurflo Water Pump can improve the operation of any water setup. Understanding the required procedures and parts is imperative for a successful setup. This instructional overview covers vital steps and the tools needed for a effective assembly.

Installation Procedure for a Shurflo Pump

- Start with collecting every instrument for shurflo pump setup. Ensure possession of tools such as a suitable screwdriver, wrench, and 50-mesh strainer.

- Attach the 50-mesh strainer to the inlet of the Pump. Preferably, use a flexible hose for inlet connections to minimize strain on fittings.

- Apply a 1/2” to 3/8” barb splicer for connecting tubing securely. To avoid leaks, opt for reinforced tubing with Oetiker clamps.

- The pump should be wired to a properly grounded outlet. A professional electrician should handle this to meet regional standards.

- Pressurize the accumulator tank to 50 PSI with filtered air or nitrogen. This is important for the best pressure performance.

- Mount a SHURflo 65 psi pressure reducer at the Pump’s inlet to secure the proper pressure setting.

- Wrap up the setup by connecting all components. Avoid overloading the motor’s amperage; incorporate thermal breakers for additional safety.

- Test the system and check the pressure switch’s functionality.

Necessary Equipment and Components for Setup

| Element | Information |

|---|---|

| 50-mesh filter | Filters debris at the pump’s inlet to ensure optimal performance. |

| Pliable hose | Ideal for connecting the inlet, lessening stress on attachments. |

| Tubing splicer | 1/2” to 3/8” connection for secure tubing attachment. |

| Pressure tank | Inflated to 50 PSI to uphold system pressure. |

| Pressure switch | Controls the pump operation based on system requirements. |

| Wiring components | Required for safe connections, ensure compliance with local electrical codes. |

| SHURflo 65 psi valve | Reduces water pressure entering the pump for consistent operation. |

Resolving Typical Issues with Shurflo Pump Systems

Learning to fix common issues with shurflo pumps improves their functionality. This section offers a diagnostic overview. It guides users through resolving typical malfunctions to maintain uninterrupted function. Troubles such as non-operation, poor flow, and excess noise are resolved using practical methods.

Common Problems and Their Solutions

Different circumstances can cause problems in Shurflo Pump systems. Below are key problems and their solutions:

- Pump runs but no water flow: Assess the water supply level, inspect piping for clogs or impairments, ensure adequate priming, and test Pump performance.

- Pump fails to start post-winterization: Review proper winterization procedures, ensure all valves are open, verify electrical connections, and inspect for potential damage to components.

- Pump intermittently starting and stopping: Inspect for leaks, check for air in the system, ensure appropriate pressure settings, and verify the functionality of the pump and pressure switch.

- Pump producing excessive noise: Examine connections for looseness, install supportive padding, shield pipes, and confirm accurate installation.

Shurflo Pump Diagnostic Manual

A complete Shurflo Pump troubleshooting guide aids in swift diagnosis. Presented here is a table outlining frequent faults and their remedies:

| Common Issue | Potential Causes | Solutions |

|---|---|---|

| Operation without liquid movement | Deficient water supply, clogs, incorrect priming | Assess water level, inspect for clogs, test Pump performance |

| Pump won’t turn on | Faulty winterization, sealed valves, power connection problems | Reassess winter steps, ensure valves are open, verify wiring |

| Pump cycles on and off | System leakages, trapped air, incorrect pressure settings | Check system integrity, purge air, calibrate pressure |

| Excessively loud operation | Unsecured fittings, poor mounting | Secure fittings, implement vibration damping, shield piping |

Comprehending the shurflo pump exploded view aids in identifying the parts causing problems is key to proper troubleshooting. Following these recommendations secures consistent performance and upkeep.

The Final Word

Understanding the Shurflo Water Pump schematic is vital for achieving maximum Pump efficiency.

Utilized in various fields like RVs and agricultural spraying, efficient setup is crucial for dependable outcomes.

Knowledge of the schematic’s components enables proficient assembly and upkeep of systems.

Installation Parts Supply is paramount for obtaining all needed Shurflo pump parts and services, offering comprehensive support, ensuring access to essential tools and components. This aids in successful installations. Through correct installation practices and proper maintenance of elements such as the strainer, Pump durability and performance are improved.

This write-up provides the insights needed to enhance overall Shurflo system operation. Employing Shurflo Pump technology alongside these installation recommendations readies users to overcome any obstacles confidently.