How to Identify Top Injection Molding Services in China

The important meeting has recently finished, your new project has the green light, the schedule is tight, and the budget is… well, let’s just say it’s tight.. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

You nod, of course. It makes sense on paper. The potential savings can be massive. But your mind is already racing. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It feels like walking a thin line between big savings and total project failure.

But here’s the catch. Procuring plastic mold company needn’t be a roll of the dice. It’s no different from any structured project. And like any project, it succeeds or fails based on the process you follow. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Ignore the nightmare anecdotes. Here’s a practical playbook to nail it.

Step One: Do Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You cannot expect overseas partners to interpret your unspoken requirements. A vague RFQ is like telling a contractor to bid on “a house.” You’ll get wildly varied quotes that are useless.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. This package is your project’s foundation.

What belongs in your RFQ?

Begin with 3D CAD models. These are non-negotiable. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This is the master blueprint for your part’s geometry.

But 3D isn’t enough. Add comprehensive 2D plans. Here you specify what 3D can’t show. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. Any seal surfaces or critical hole sizes must be clearly labeled.

Next up, material. Avoid generic terms like “Plastic.” Nor just “ABS.” Get precise. If you need SABIC Cycolac MG38 in black, say exactly that. Why? Because resin grades number in the thousands. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with what is plastic mold.

Your supplier might propose substitutes, but you must set the baseline.

Lastly, add your business data. What is your Estimated Annual Usage (EAU)? You must specify if it’s a 1K-part tool or a 1M-part production run. Tool style, cavity count, and unit cost are volume-driven.

Finding the Right Supplier

Okay, your RFQ package is a work of art. now, who do you send it to? Online sourcing is global but crowded. Finding suppliers is simple; finding quality ones is tough.

You’ll probably kick off on Alibaba or Made-in-China. They let you survey dozens of suppliers quickly. But think of them as a starting point, not the finish line. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

Still, you must dig deeper. Consider using a sourcing agent. True, they charge a fee. But a reputable agent brings pre-screened factories. They handle local liaison and oversight. As a newcomer, this offers priceless security. It’s schedule protection.

Another tactic: trade exhibitions. If you can attend, shows such as Chinaplas transform sourcing. Nothing beats a face-to-face conversation. Inspect prototypes, interview engineers, and sense their capabilities. And don’t forget the oldest trick in the book: referrals. Tap your professional contacts. A solid referral can be more valuable than any ad.

Separating Real Suppliers from Pretenders

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. the quotes will start trickling in. Some prices will undercut logic, others will shock you. Now, sift through and shortlist 2–3 reliable candidates.

What’s the method? It’s a bit of an art and a science.

First, look at their communication. Are their replies prompt and clear? Is their English good enough for complex technical discussions? But the key: do they probe your RFQ? Top vendors will critique and inquire. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” Consider that a big green light. You know they know their stuff. A supplier who just says “No problem” to everything is a walking red flag.

Afterward, verify their technical arsenal. Ask for a list of their equipment. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. Don’t pick a micro-molding shop for large components.

Finally, inspect the factory. Skipping this is a mistake. Just as you interview hires, audit suppliers. You can travel or outsource a local inspector. They dispatch an on-site auditor for a day. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. That small investment can save you thousands.

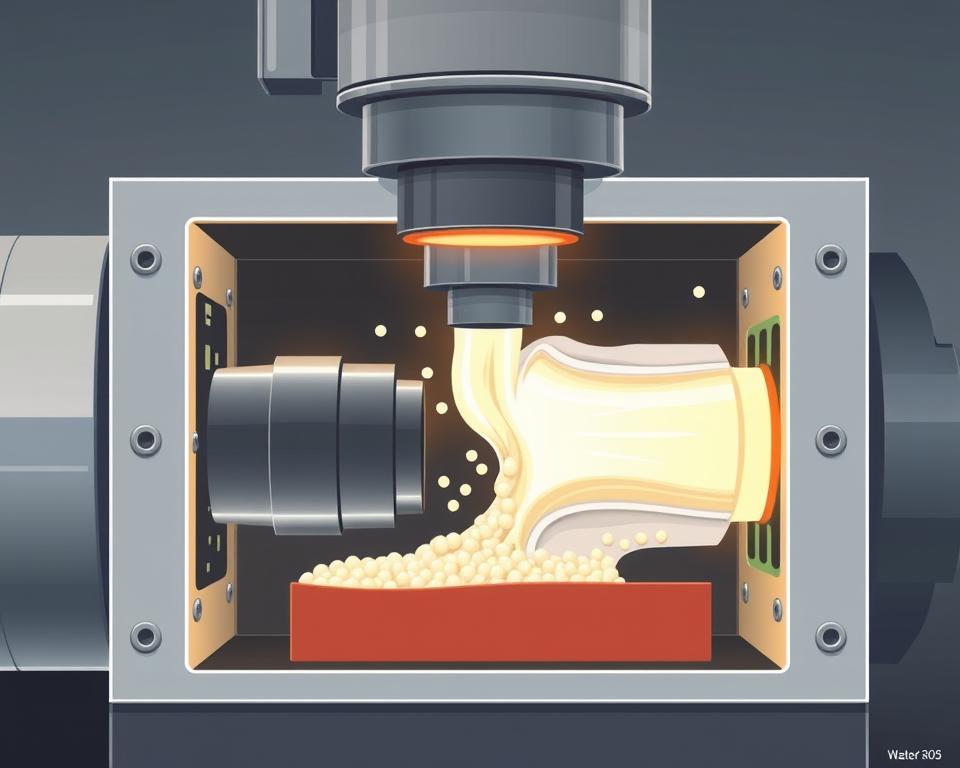

From Digital File to Physical Part

After picking your vendor, you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the process kicks off.

Initially, expect a DFM report. DFM stands for Design for Manufacturability. This is your supplier’s formal feedback on your part design. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. Comprehensive DFM equals a top-tier supplier. It’s a two-way partnership. You iterate with their team to optimize the mold.

With DFM sign-off, toolmaking begins. Weeks on, you receive the thrilling “T1 samples shipped” notification. These represent the first trial parts. They are your moment of truth.

Be prepared: T1 samples are almost never perfect. That’s standard process. Look for small flaws, slight size errors, or surface marks. You critique, they refine, and T2 plastic mold in China parts arrive. It could require several iterations. Build buffer time for sample iterations.

At last, you get the perfect shot. It matches all specs, has a pristine finish, and works as required. This becomes the “golden sample.” You ratify it, and it becomes the quality yardstick for production.

Completing the Sourcing Journey

Landing the golden sample is huge, yet the project continues. Now comes full-scale production. How do you ensure that the 10,000th part is just as good as the golden sample?

Implement a robust QC plan. This often involves a pre-shipment inspection. Bring in an external QC firm. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. You receive a full report with images and measurements. Only after you approve this report do you authorize the shipment and send the final payment. This simple step prevents you from receiving a container full of scrap metal.

Lastly, plan logistics. Clarify your Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, shifting all transport to you? These details have a big impact on your final landed cost.

China sourcing is a long-haul effort. It’s about building a relationship with your supplier. Treat them like a partner, not just a line item on a spreadsheet. Clear communication, mutual respect, and a solid process are your keys to success. No question, it’s demanding. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’ve got this.